Other manufacturers with similar products

EPD: Steel frame for doors, 4.33 in (110 mm), 0.91x2.13 m, 7.05 kg/m3, 22.31 kg/unit, Mercury Thermal Break Frames, Assa Abloy

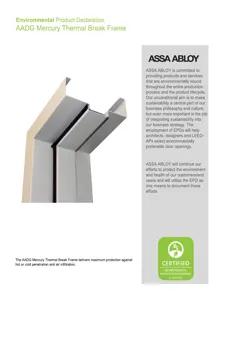

Introducing the Mercury Thermal Break Frames—combining energy efficiency with aesthetic appeal. These frames are designed to minimize heat transfer, enhance comfort, and offer long-lasting performance, making them ideal for any setting.

This steel frame for doors features a sleek design with thermal break technology, providing superior insulation. Its robust construction ensures durability while allowing easy installation and user-friendly interactions.

Mercury Thermal Break Frames are installed i...

Manufacturer:

Assa Abloy

Group:

Country of production:

Product name:

Steel frame for doors

Commercial names:

Mercury Thermal Break Frames

Category:

Steel and other metals

Class:

Structural steel and steel profiles

Type:

Sections

Environmental impacts

Global Warming Potential (A1-A3):

61 kg CO2e/unit

Technical specification:

4.33 in (110 mm), 0.91x2.13 m, 7.05 kg/m³, 22.31 kg/unit

Available units for calculation:

unit, kg, ton

Unique identifier (OCLID):

66bf93cac65bfc7e406fd752

Sustainability data background information

EPD number:

4789922565.101.1

EPD program:

UL Environment

Publication year:

2021

Product Category Rules (PCR):

PCR Part B: Commercial Steel Doors and Steel Frames, Version 2.0, UL Environment. Published September 2020.

Environmental standard:

ISO 14040, EN15804+A1

Data source:

EPD AADG Mercury Thermal Break Frame

Verification status:

Third-party verified (as per ISO 14025)

Upstream database:

GaBi